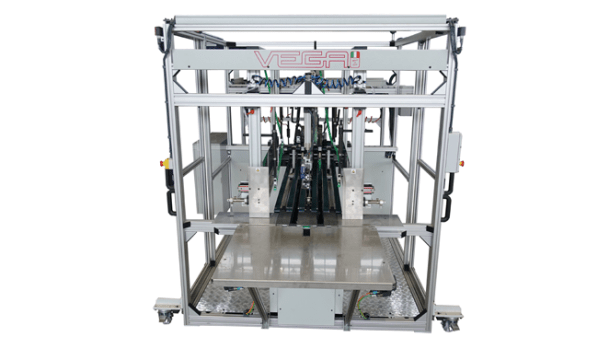

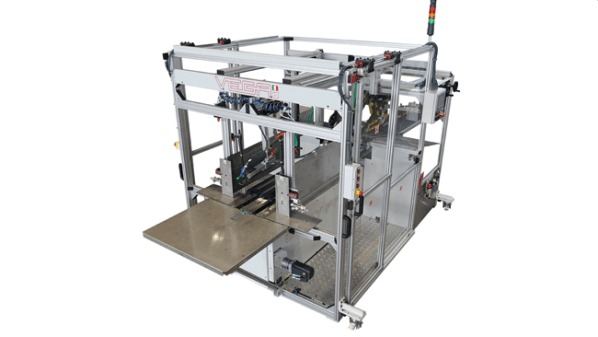

Vega Easypack

batch counter ejector for straight line, crash lock bottom and 4/6 corners boxes

Positioned at the exit of the pressure belt of any folder gluer, the Vega Easypack counts and separates the shingled folded boxes into a batch of pre-determined quantity while maintaining the initial shingled sequence. The counting is made by a laser photocell.

A motorised belt is installed between the delivery unit and the batch counter ejector and allows an operator to view the boxes for quality control.

While the pre-determined sequence of boxes is pushed forward into a bundle by the thrusters, a synchronised retractable sliding belted support system slides out to maintain the initial boxes of the next batch raised in their shingled sequence until the thrust units have returned to their starting position ready for the next batch. At this time, the first boxes of the next batch are dropped into the thrust area while the belted support returns to its beginning position.

When producing lock-bottom boxes the thrust units can be set to work independently to accompany the box through the thrust phase.

Two adjustable upper guides serve to maintain alignment of the batch during the thrust phase, and two lateral guides work to assure lateral alignment.

When producing bundles which necessarily have an odd number of boxes and which need to be turned over for correct packaging (such as lockbottom boxes) it is possible to set two sequences for the two different quantities (example 7 + 8).

The EASYPACK can work in automatic in line with an arch strapping machine (optional) in the case of linear boxes or Twinbox linear designs and a high variety of 4/6 corners boxes. In case of crash lock bottom boxes an operator is needed between the EASYPACK and the strapping unit for turning over a half of the bundle for stacking purposes before manually sending it off to the strapping machine.

The EASYPACK can increment production capacities for all types of

boxes. Even when an operator is necessary for turning over half of the batch, hourly production can be incremented up to 40% and the operator manual work will be highly reduced.

The work height at the package take-off zone is 900 mm.

| Dimensions / Specifications in a snapshot | |

| Width | max - 1500mm; min - 200mm |

| Length | max - 1200mm; min - 150mm |

| Stacking height | max - 300mm |

| No cycles/min | max - 20 |

| Installation height | max - 930mm; min - 870mm |